The Early Years

This photo shows Walter Franscioni driving a late 1800's tandem hay wagon hitched with an eight-horse team. They were on their way to the Soledad Train Station. In those years the train track ended in Soledad. Because of this, the locomotive would be turned around on a special turntable, called a roundhouse. The San Francisco Fire Department bought the hay because fire apparatus were pulled by horses during that time.

Hardship

During the famous drought of 1897-1898 Fernando Franscioni had no choice but to walk his teams of work horses to Hanford in order to find useable grazing land. He made the trip with Desiderio Binsacca. They had to feed their hungry animals along the way by climbing trees and cutting off the leaves. Fortunately, Louis Giacomazzi, his father-in-law, owned land there and Fernando was able to feed his horses for almost a year until it finally rained. They then returned with their horses to their leased land at Rancho Zabala.

-As Told By Ernie Binsacca

-As Told By Ernie Binsacca

J.I. Case 30-60

In the early years Walter and Fernando Franscioni grew mostly grain, which needed to be harvested. Fernando and Walter Franscioni mechanized early on by buying a threasher and a steam engine. In order to pay for their major investment, they custom harvested grain for other farms throughout Monterey County. In 1913, Walter traded the steam engine for a modern kerosene tractor. His choice was a J. I. Case 30-60, one of the largest tractors of its time, weighing nearly 26,000 pounds. It was well known around Clark Colony and the Soledad Mission area that Walter Franscioni owned a "Big Engine". Many farmers would pay Walter Franscioni to go to their farm and power their newly dug deep wells during the testing and development procedure.

|

This is the Walter Franscioni Dairy Barn. As business grew, the barn was expanded in the 1920’s to double its square footage. Today it is used for tractor storage

c. 1912 |

This was the old feed yard for finishing cattle before they were taken to market. By the 1990’s that era of farming hadended for Franscioni & Griva.

|

An early photo of the homestead. Many of the buildings pictured here are still standing today.

1918

1918

Gildo Griva poses next to his 1924 Buick Master Sedan.

A New Era

Advancement of Irrigation and Water Systems

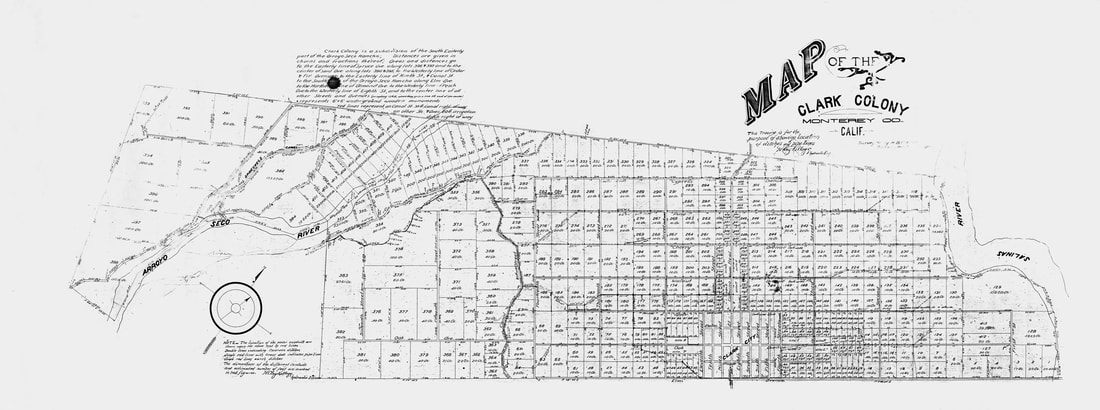

Above is a 1905 map of Clark Colony, presently recognized as Greenfield, CA. Franscioni & Griva Corporation was founded in what used to be known as Clark Colony. Clark Colony was founded in 1905, when land was auctioned off by Rancho Arroyo Seco for $37.50/acre, This price included water rights to the land. The Clark Colony Water Company (CCWC) was formed in 1905 to deliver water to the CCWC shareholders. CCWC shares were given to the landowners who bought the auctioned property. Clark Colony settlers then went on to build the largest gravity flow irrigation system in the Salinas Valley.

A New Technology

Deep Well Irrigation

Even though the Clark Colony water canal supplied high quality water to the farm, it was dependent on the seasons and drought. A solution was found by Claus Spreckels, who developed deep well irrigation in the late 1800’s. Walter Franscioni drilled his first deep well, powered by an oil engine, in 1912. Many advances have happened since then, and now many of our wells are powered by variable frequency drives, which saves electricity and reduces maintenance.

|

Franscioni Griva bought their first sprinkler irrigation system in 1954. The pipes in this system were made of 4” aluminum. These early pipes had a 12” steel riser with a Rainbird sprinkler. They were heavy to move and difficult to unlatch because they had a spring loaded ball socket.

|

1905 Byron Jackson Pump

|

Modern well. 2018

Advancements in Agriculture

CB Hay Bean Harvester

Franscioni & Griva started planting dry beans in 1917 for the WWI effort, and are

still growing dry bean crops today. Pictured above is Franscioni & Griva’s first "new" bean harvester: CB Hay 1937-No7. The CB Hay Harvesters separated the beans from the chaff. Afterwards, the clean beans were brought up to the top of the harvester and into what is known as the dog house. This is where the beans were put into 100-pound sacks and sewn closed. Finally, the sealed bags were then sent to the ground using a chute, and would later be loaded onto a wagon.

still growing dry bean crops today. Pictured above is Franscioni & Griva’s first "new" bean harvester: CB Hay 1937-No7. The CB Hay Harvesters separated the beans from the chaff. Afterwards, the clean beans were brought up to the top of the harvester and into what is known as the dog house. This is where the beans were put into 100-pound sacks and sewn closed. Finally, the sealed bags were then sent to the ground using a chute, and would later be loaded onto a wagon.

Sugar Beet Production

After the tops of the sugar beets were removed, they were placed in the back of trucks that took the crop to the railroad station.

Introduction of the Beet Wheel Harvester

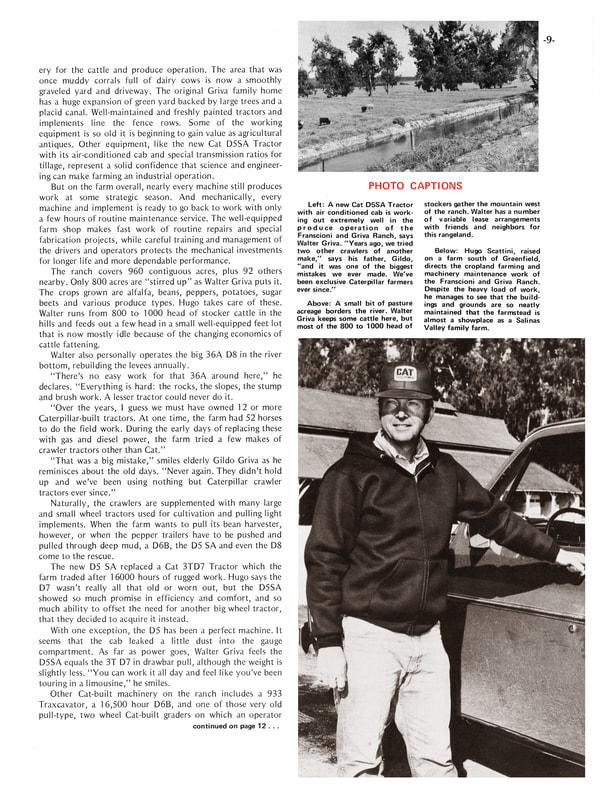

Mechanization became available to sugar beet harvesting with the introduction of the beet wheel harvester. This machine could perform quite a few steps at once: pulling the beet up, cutting the top off, and depositing it in the back of the truck. In the above photos, the Marbeet Harvester is shown pulling up the beet and cutting the top of it off mechanically before depositing it in the back of the beet truck.

Chili Production

A photo of chili production on the Franscioni & Griva Ranch. The workers are hand-picking the chilis after the crop has been defoliated.

2001

2001

Franscioni & Griva in Print

Thank you for visiting our page. Please contact us with any questions.

|

Franscioni-Griva Corporation est. 1868

|

F&G Vineyard, LLC. / Griva Vineyard est. 1998

|